AccurlCMT 175 TON | 3200MM CNC PRESS BRAKE | 7 AXIS | ENERGY SAVING TECH | 3D CONTROLLER

Confirm if additional costs apply

-

-

-

-

+17

+17

AccurlCMT 175 TON | 3200MM CNC PRESS BRAKE | 7 AXIS | ENERGY SAVING TECH | 3D CONTROLLER : $124,000 AUD ($136,400 Inc. GST)

Confirm if additional costs apply

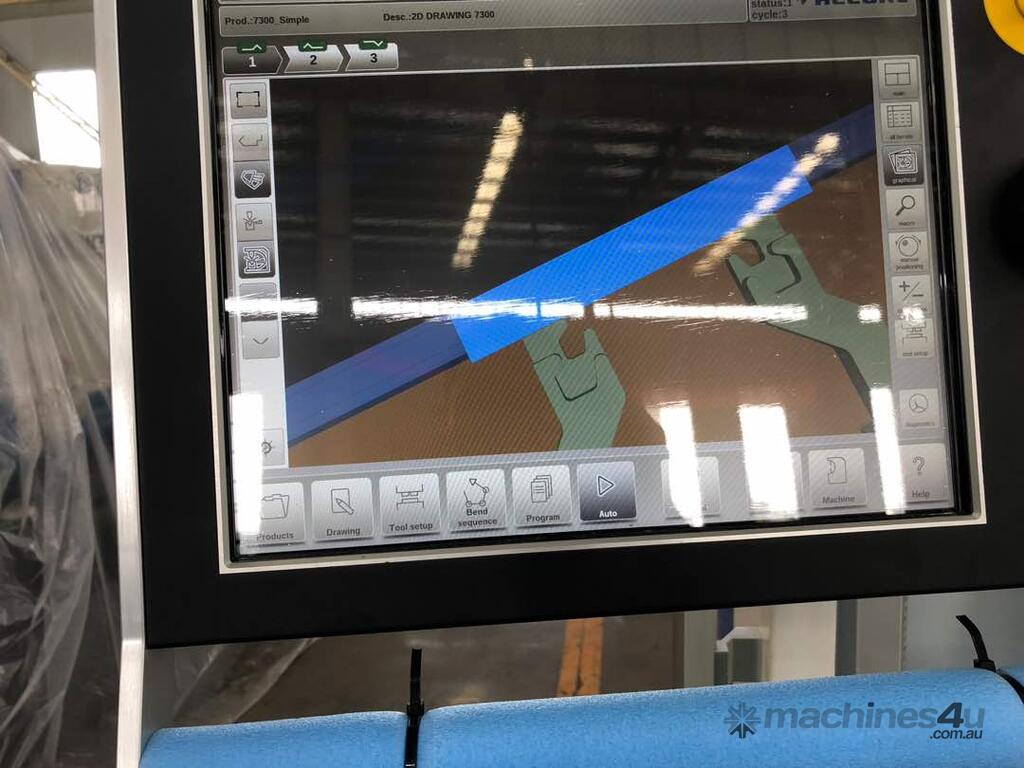

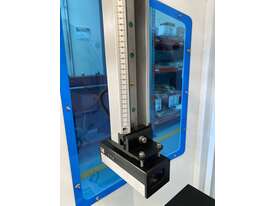

AccurlCMT 175 ton x 3.2m CNC Press Brake with a Delem DA-66T Graphical controller

Complete Machine Tools has a new best in class CNC press brake on offer which not only offers the best price to performance/options in its class but also features previously only available on high end expensive European machines.

The AccurlCMT 175 ton x 3.2m CNC press brakes offers some of the best features on the market such as -

- 175 ton capacity

- 3200mm bed length

- Inverter to control main motor on/off function allowing for up to 50% in energy reduction usage

- ECO / every saving technology

- Siemens inverter / main motor

- Givi linear scales

- Hoerbiger hydraulic system

- Huge opening between tools

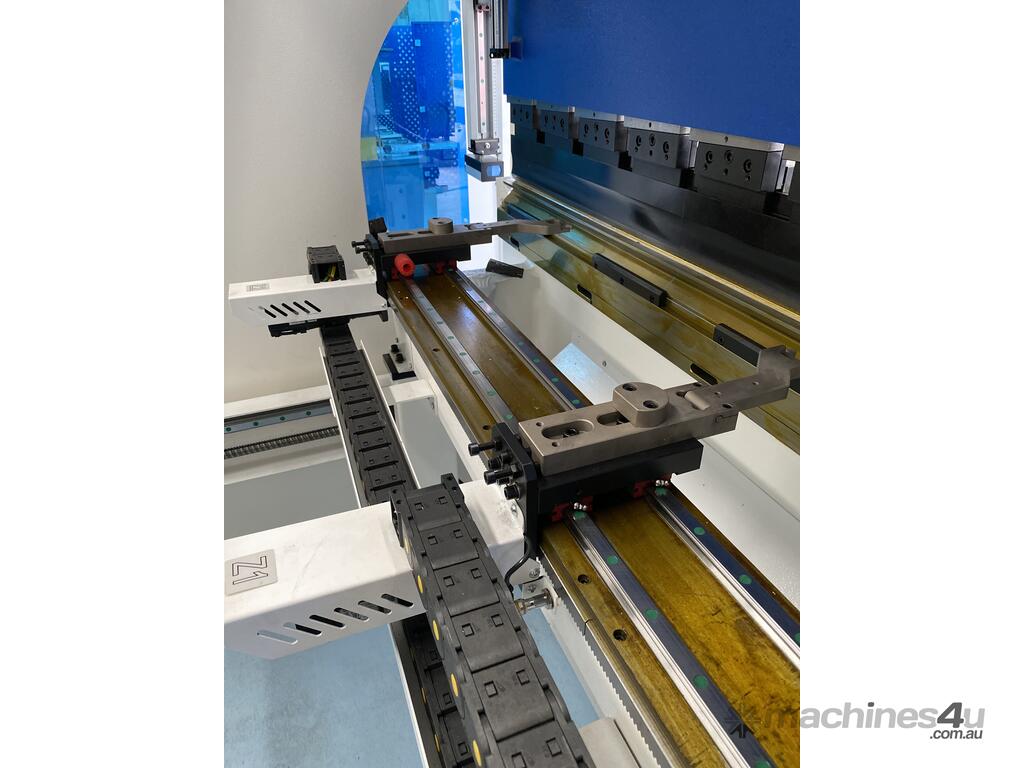

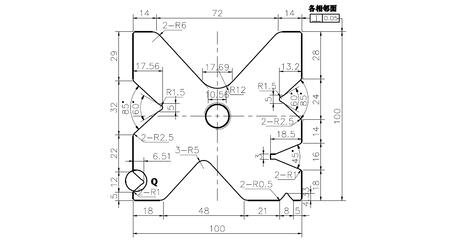

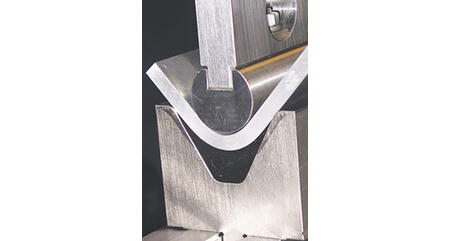

- 60 X 60mm multi vee bottom self centering die

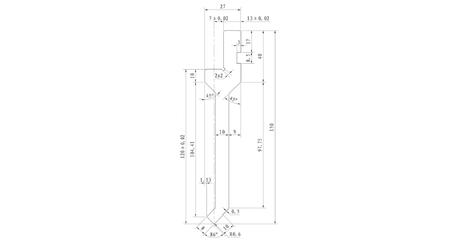

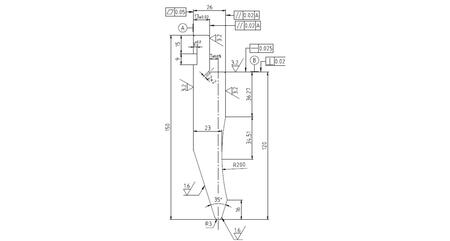

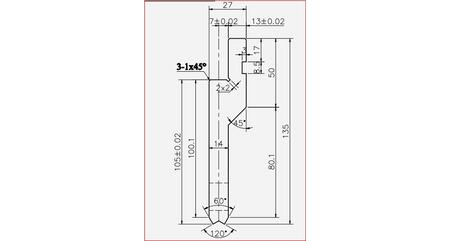

- Top tooling segmented with a 1mm radius

- 450mm throat

- Top tool clamping allowing removal of tooling from the front of the machine, no more timely removal of tools from the side of the machine.

- Inbuilt LED status lights in the cylinder covers

- Delem DA-66T controller

- Mechanical CNC controlled crowning done via the controller

- Lasersafe guarding system

- Rules on up and bottom beams for station positioning

- 2 YEAR WARRANTY ON PARTS (not including Lasersafe)

In todays age with electricity prices in Australia being one if the highest in the world it makes sense to steer towards machines that can offer a reduction in your electricity costs. With the AccurlCMT Europro range you get that technology at an affordable price which previously was out of the reach of most.

With a Siemens inverter / main motor the inverter switches the main pump on/off at the appropriate times. At the top of stroke the motor will switch off but as soon as the foot pedal is pressed the main motor is switched on. This reduces the amount of energy the machine needs by up to 50% but also the oil temperature remains low, componentry has less wear and tear so the benefits are huge with this technology the AccurlCMT machines have on as standard.

Confirm if additional costs apply

New LINIA PRECISION CNC PLASMA CUTTING MACHINE | 125A HYPERTHERM | WIRELESS REMOTE | DUAL DRIVE

New LINIA CNC PLASMA CUTTING MACHINE | HYPERTHERM 65A | 1.5M X 3M | WATER TABLE

New LINIA PRECISION CNC PLASMA CUTTING MACHINE | 45A HYPERTHERM | WIRELESS REMOTE | DUAL DRIVE

New PUMA HNM-6A | 6MM VARIABLE ANGLE NOTCHER & PUNCH | DUAL STATION

New LHC HEAVY DUTY PRESSES | 25 - 500 TON

New LINIA CNC PLASMA CUTTING MACHINE | HYPERTHERM 45A | 1.5M X 3M | WATER TABLE

New LINIA PRECISION CNC PLASMA CUTTING MACHINE | 65A HYPERTHERM | WIRELESS REMOTE | DUAL DRIVE

New LINIA CNC PLASMA W/DRILL HEAD | USE YOUR OWN PLASMA

New PUMA HNM-6 NOTCHER | 6MM CAPACITY | FIXED ANGLE | HYDRAULIC

New LINIA CNC PLASMA CUTTING MACHINE | HYPERTHERM 85A | 1.5M X 3M | WATER TABLE

New MANUALLY ADJUSTABLE CROWNING BOTTOM PRESS BRAKE TABLE | 4000MM LENGTH | 240MM WIDE

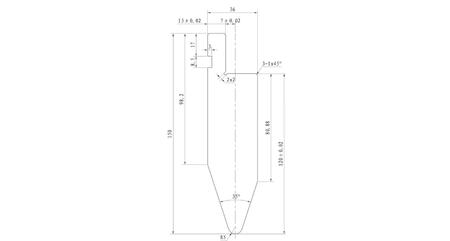

New 100MM SQ X 3100 MULTI VEE DIE | INCL DEEP V FOR OVER BENDING

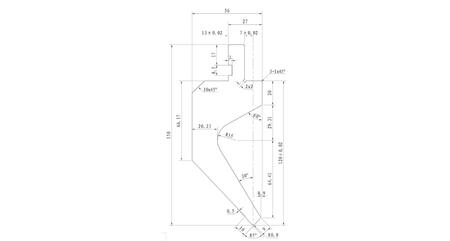

New 86 DEG / R0.6MM OFFSET PRESS BRAKE TOOLING TOP PUNCH | EURO TYPE

New 35 DEG / R3MM PRESS BRAKE TOOLING TOP PUNCH | EURO TYPE

New PRESS BRAKE RADIUS BAR HOLDER TO ACCOMDATE BARS UP TO 20MM DIA | EURO STYLE

New 85 DEG / R0.8MM GOOSENECK PRESS BRAKE TOOLING

New RADIUS BARS | 8 - 60MM DIAMETER KEPT IN STOCK

New 35 DEG / R5MM BULL NOSE PRESS BRAKE TOP PUNCH | EURO STYLE

Facebook

Facebook Twitter

Twitter

Email

Email

Print

Print