AMOB SECTION ROLLS | HYDRAULIC | DRO | PINCH TYPE | 80MM SHAFT | HEAVY DUTY | EUROPEAN

AMOB SECTION ROLLS | HYDRAULIC | DRO | PINCH TYPE | 80MM SHAFT | HEAVY DUTY | EUROPEAN : $33,000 AUD ($36,300 Inc. GST)

Amob section rolling machines are manufactured in Portugal to the strictest quality controls. All machining, welding and assembly are done in house to make sure QC is kept to a very high standard. Amob manufacturers some of the biggest section rolling machines in the world and has a great deal of knowledge in that market segment.

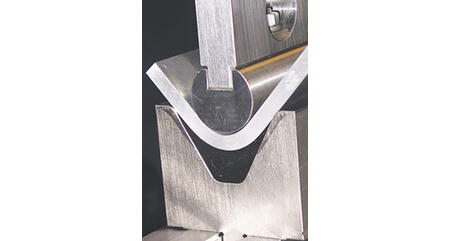

The Amob MAH 80/3AC is a hydraulic dual pinch type machine that can be used both in the vertical or horizontal position without any consideration for the hydraulic tank meaning the tank is a sealed unit and has no issue in wither position. The rolls have a programmable DRO for repeatability.

The support arms are hydraulic and have a very long stroke movement and are also fixed making them a lot more rigid and enabling smaller diameter circles to be rolled over the traditional pivot type support arms.

Both bottom rolls are hydraulic and are a pinch style. A very solid well made set of section rolls!

AMOB MODEL: MAH 80/3 AC

- SPECIFICATIONS/STANDARD EQUIPMENT:

THREE DRIVEN ROLLS

GUIDE ROLLS HYDRAULICALLY ADJUSTED

BOTTOM ROLLS PROGRAMMABLE DIGITAL READOUT

HYDRAULIC ADJUSTMENT OF BOTTOM ROLLS OVERLOAD PROTECTION

HORIZONTAL/VERTICAL WORKING POSITION

FOOT PEDAL CONTROL WITH EMERGENCY STOP

POWER: 7 kW

RPM: 5.5

ROLLS DIAMETER: 245MM

SHAFT DIAMETER: 80

MACHINE WEIGHT: 1650 KG

DIMENSIONS: 1379MM X 1305MM X 1612MM

- STANDARD ROLLS CAPACITY IN MILD STEEL:

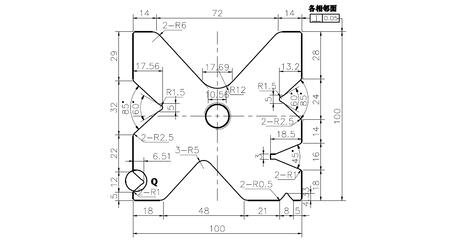

FLAT BAR ON FLAT MAXIMUM: 100MM X 20MM 2000 DIA.

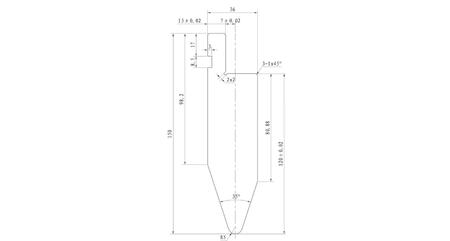

FLAT BAR ON EDGE MAXIMUM: 120MM X 30MM 600 DIA.

SQUARE/RECTANGULAR BAR: 45 SQ 1000 DIA.

ROUND BAR: 60 DIA. 1000 DIA.

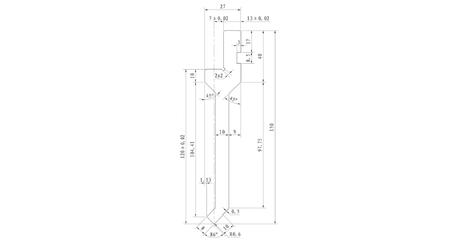

ANGLE OUTSIDE: 80MM X 80MM X 8MM 1600 DIA

ANGLE INSIDE: 80MM X 80MM X 8MM 1800 DIA

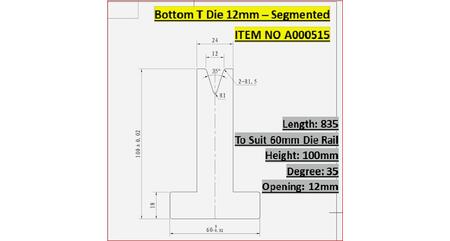

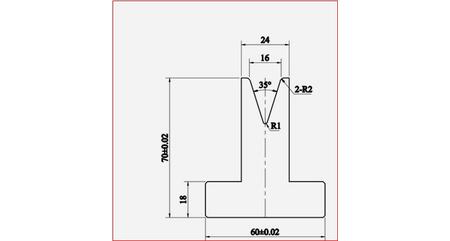

T OUTSIDE:80MM X 80MM X 8MM 1400 DIA.

T INSIDE: 80MM X 80MM X 8MM 1400 DIA.

T ON EDGE: 80MM X 80MM X 8MM 1400 DIA.

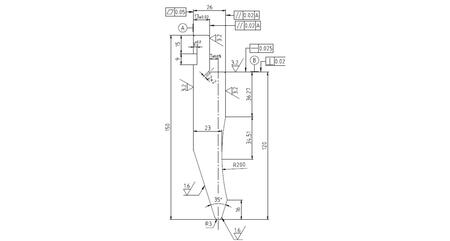

UPN 140 OUTSIDE: 1000 DIA.

UPN 140 INSIDE: 1000 DIA

- GENERAL DESCRIPTION & STANDARD EQUIPMENT

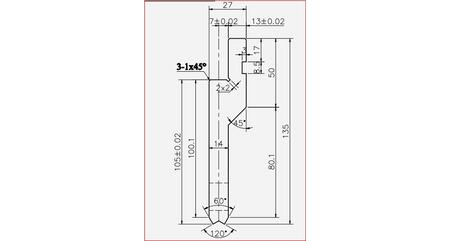

Body Steel Construction fully hydraulic 3 rolls section bending machine by means of elliptical movement

Machine operates on horizontal | vertical position

3 Hydraulic Driven Rolls and high torque planetary gearbox

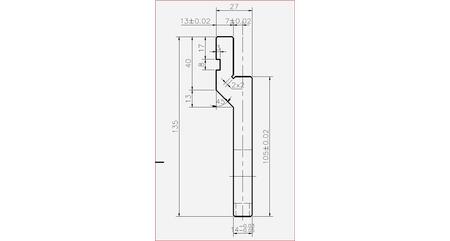

Independent Hydraulic Adjustment of both side bending rolls reducing to minimum the straight edge (pre-bending) on suitable sections.

Automatic Peripheral Speed Compensation (power not scarified)

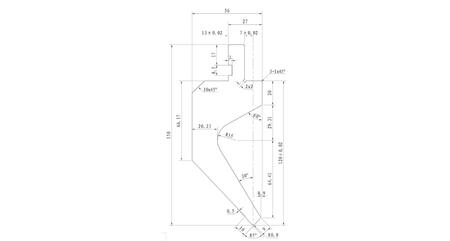

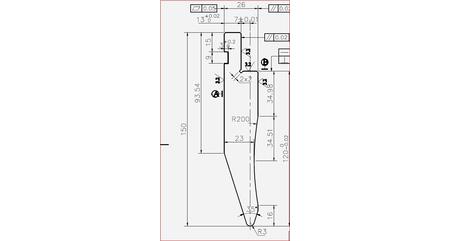

Mechanical Vertical Guiding Rolls IN-OUT allowing positioning following a wide variety of sections according to their shape and dimension guaranteeing proper guiding while rolling;

Bending Rolls L.E.D. Readouts two electronic digital displays mounted on the operators console indicating position of left and right bending roll (X & Y axis). Stop Position is programmable.

Control Panel from where all machine functions can be controlled

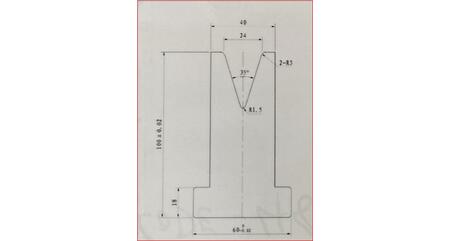

3 Hardened Standard Rolls built in 3 sections each adjustable covering a vast list of profiles as per flat bar on edge and on flat position, T bar, angle profile all kind of bar profiles between others special.

Surface induction treatment in all tools in contact with profile being bent

FR 3 Shafts material

CE Certificate

Facebook

Facebook Twitter

Twitter

Email

Email

Print

Print