LEADWELL V-120i HEAVY DUTY MACHINING CENTRE | FANUC | X -3000MM | CTS | 4TH AXIS READY

LEADWELL V-120i HEAVY DUTY MACHINING CENTRE | FANUC | X -3000MM | CTS | 4TH AXIS READY : $265,000 AUD ($291,500 Inc. GST)

LEADWELL use only top quality well-ribbed castings. Finite

Element Analysis (FEA) is used on each new casting to determine

the size and location of all internal ribs ensuring high torsion

stiffness and minimum vibration. The cast iron base column,

saddle, headstock,& tables have over 10 times the dampening

capacity of those made from steel, resulting in superior cutting

performance.

High quality linear guide ways feature zero clearance and

fully-loaded carrying capacity in all directions. The ways

consume less power and requires no adjustments.

They linear guide ways out perform all other types of ways

used today. Additionally, each way is automatically lubricated

independently to increase life.

SPECIFICATIONS

Capacity

X-Axis travel 3000mm

Y-Axis travel 1000mm (40in)

Z-Axis travel with BT-50 920mm (36in)

Distance from table (pallet) top to spindle end 150mm – 1070mm

Distance from column front to spindle centre 1000mm(40in)

Table

Size of working surface 3030mm x 1000mm

Permissible mass of workpiece 1800kg

Table working surface configuration

18T x 125 x 8

Height from floor to table top 1105mm

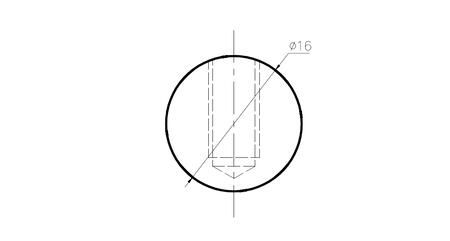

Spindle

Spindle speeds 6000RPM

Number of spindle speed ranges 1

Spindle nose (nominal size, NO.)

7/24 Taper NO50

Spindle bearing inner diameter 90mm

Transmission H.T.D Belt

Feedrate

Rapid traverse 12/15/15 m/min

Feedrate 5m/min

Jog federate 1260mm/min

A.T.C

Toolshank (nominal size, NO.) BT-50

Retention knob (nominal size, NO.)

MAS-P50T-1

Tool storage capacity 24 S.T.D

Max. tool diameter (with adjacent tools) 100mm

Max. tool diameter (without adjacent tools) 150mm

Max. tool mass 15kg

Max. tool length 300mm

Tool change time (tool to tool) 3

Tool change time (chip to chip) 10

Tool selection Random

CHIP REMOVAL

This simple and efficient design uses chip augers on both sides of the machine and provides high volume coolant to wash the

chips from the work area.

The augers move the chips into the disposal container, which eliminates the need for an operator to manually remove chips.

This system eliminates operation intervention and reduces non-cutting time.

RIGID TAPPING

The encoder is attached to the high-performance spindle motor. The spindle is then synchronized with the Z-axis motion.

This synchronization eliminates the need for expensive floating tap holders and prevents thread distortion and thread pullout.

DOUBLE NUT DESIGNED BALL SCREWS

LEADWELL use only premium quality preloaded double-nut ball screws.

Each ball screw is accurately aligned parallel to the guide ways and anchored

at both ends. They are then pre-tensioned to improve machine stiffness.

The rotational torque variation is inspected to guarantee a non-binding, highly accurate, and long running component. With this design the V-Series can exceed customer requirements for accuracy and maximum life

COUPLED SERVO MOTORS

The servo motors are connected to the ball screws with rigid shaft couplings.

These couplings ensure that even under severe loading from sharp corner machining,

precise interpolation is achieved.

This design is superior to both belt driven and flexible shaft coupling designs.

V-series motors have 1,000,000 pulse encoders for high accuracy positioning of

linear axes. Motors are the same between X & Z which reduces spare part requirements.

CARTRIDGE TYPE SPINDLE

The heavy-duty spindle utilizes FAG, NSK or SKF bearings to allow heavy cutting.

Oversized disk springs used to hold the tool in the spindle are tested for long life.

The high retention force of the springs reduce tool movement, improve tool life, allow heavier cutting, reduce chatter, & create a better part finish.

This spindle is prepared to easily add the CTS option.

FEATURES & SPECIFICATIONS:

BT50 spindle

Enlarged Y axis motor

40 bar high pressure coolant system

CTS preparation, filtration and pump

Floor mounted control

Fanuc Oi-MF 10.4” screen and manual guide i

M30 auto power off

Spindle coolant ring

Top cover with rail

Coolant gun

Tool life management

Transformer

Interlock switch for front door

Alarm lamp

Heat exchanger

Rigid tapping

Auto counter for work piece

Full enclosed guard

4000mm front door opening

Spindle air purge with valve

Chip conveyor towards the back of the machine

Rear chip conveyor to feed material to the side of the machine

24 arm type ATC

Tool overload detection

MPG hand wheel

2 year Fanuc warranty

Circular interpolation

Florescent / LED lights on both sides and rear of the inside of the machine

6000 rpm spindle speed w/ball bearing and oil chiller

Packing

Facebook

Facebook Twitter

Twitter

Email

Email

Print

Print